The Nanomining (www.nanomining.eu) is one of four projects selected in the first joint EU-Mexico call (announced in 2009) within the priority NMP.2010.1.2-4 pt. Adding Value to Mining at the Nanostructure level. The time of realization is 3 years (2010-2013).

Partners from Three European countries (Poland, Germany, France), Mexico and Canada are involved in the Project Consortium. Polish Partners have significant input to the Project and are nearly one third of the whole Consortium, which consists of the following organizations:

1. Instytut Obróbki Plastycznej (INOP), Polska, - Coordinator

2. Centro de Investigación en Materiales Avanzados, S.C. (CIMAV), Mexico,

3. Universidad Autónoma de Ciudad Juárez (UACJ), Mexico,

4. Centro de Investigación en Química Aplicada (CIQA), Mexico,

5. Tamuse Systems (Tamuse), Mexico,

6. IfU Diagnostic Systems GmbH (IfU), Germany,

7. Instytut Metali Nieżelaznych (IMN), Poland,

8. PROJECTION PLASMA SYSTEME (2PS), France,

9. Tessonics Inc. (Tessonics), Canada,

10. Uniwersytet Medyczny im. Karola Marcinkowskiego w Poznaniu (UMP), Poland.

The Project deals with silver recovery, silver nanoparticles and silver based nanostructured composites. The environmental problems related to jarosite are significant all over the world. In many cases jarosite waste contains precious metals and especially silver in quantities that make their extraction attractive.

The Nanomining aim is to develop materials starting from waste jarosite through nanoparticle manufacture to end products addressing the whole value chain. The processes assessed are of interest for their applications in biomedicine and electrical component industry.

Project goals:

The main goal of the Project is to develop:

1. Clean and efficient procedure of silver recovery from waste: Combined Mechanical Activation – Thermal Oxidation Processing of jarosite type residues to alleviate and accelerate the following precious metal leaching;

2. Combined nanotechnology of biological synthesis (using Mexican plants) of Ag nanoparticles and its deposition on implant surfaces by electrophoretic, spraying and other techniques;

3. Nanostructuring technology of Silver based nanocomposites manufacturing for electrical contact applications.

4. Pilot production and trials of developed Ag nanoparticle modified implants and Ag based nanostructured composites:

- Hydroxyapatite Ca10(PO4)6(OH)2) coated implants which are widely used in orthopaedic surgery because of their good biocompatibility related to the osteoconductive properties of calcium phosphate coating;

- Ag-SnO contacts for electrical systems; these composites combine high resistance to welding and to electric arch erosion of the refractory phases with the high electric and thermal conductivities

Methods:

Three groups of technologies were examined:

1. Thermal oxidation and reduction processes of mechanically activated Ag and Zn containing waste products;

2. Biosynthesis of Ag nanoparticles and its'incorporation into Hydroxyapatite coatings;

3. Silver based nanostructured composite forming technologies of Ag-SnO and other contacts for electrical systems.

The scanning and transmission electron microscopy, precision chemical analysis, atomic force microscopy, spectroscopy and other methods were applied to study and products characterization. The in-vivo and in-vitro tests of AgNp modified implants were performed.

Ag NPs of size 2–18 nm have been synthesised, characterised and incorporated into Hydroxyapatite implant coatings. The Ag NPs deposition processes to coat surgical implants were developed using Ag nanopowders. The Ag-based nanocomposite fabrication methods were chosen and the laboratory samples of end-user requested parts were made. The results are opening the stage to novel Ag-based nanomaterials that could create new products as well as novel biosynthesis mechanisms that could be exploited in other ways.

The Nanomining project generated following results:

1) Mechanically Activated Thermal Oxidation (MATO) Technology and MATO machine for Jarosite Treatment:

a) Fluidized Bed Reactor for Jarosite MATO processing

b) Rotary Furnace for Jarosite MATO processing

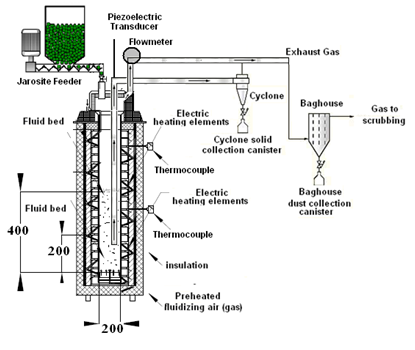

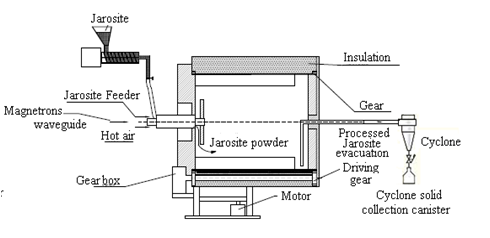

There were two strategies examined in the Project: jarosite mechanical activation –Jet Mill + Microwave Rotary Furnace Oxidation and Jet Mill + Fluidized Bed Oxidation. A pilot fluidized-bed oxidation reactor was built to carry out the pilot experiments under the operating conditions of interest and to make possible observation and recording the process parameters during the runs.

|

|

| Fig. 1a. Fluidized bed reactor scheme |

Fig. 1 b. Schematic diagram of the microwave heating system |

2) MAREC Technology Penoles Metallurgical Zn containing Slag Treatment

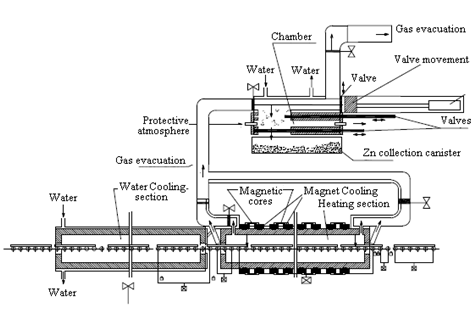

The Zn reduction MAREC (Mechanical Activation-Thermal Reduction) process was developed and elaborated for Zn containing waste. The new furnace design was developed by INOP for reduction of Zn and Pb, and collection of the product in protective atmosphere (Fig. 2). Application of magnetic field allows to create the high porous fluidized bed similar to those of fluidized bed reactor. MAREC technology was examined in the laboratory furnace using two types of waste: W1- after melting, W2 –after electrolytic processing. The reduction of Zn was made in reduction atmosphere (75% H2 + 25% N2)

|

| Fig. 2. Design of magnetic fluidized bed furnace for Zn reduction |

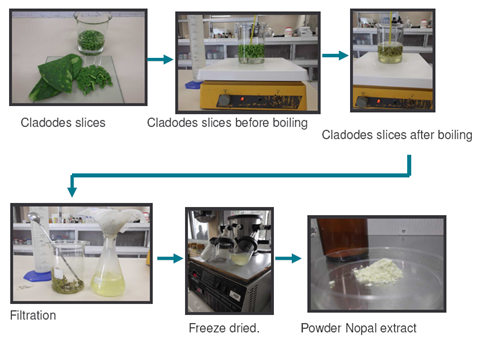

3) Ag Nanoparticles bio-synthesis using dessert plant

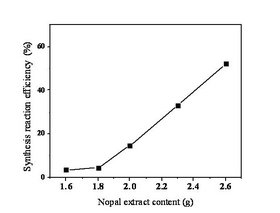

The synthesis of silver nanoparticles of different chemical compositions, sizes and controlled monodispersity was developed and elaborated. Nanoparticle organic content control is a recent innovation of newly emerging synthesis methods. At the present, there is a growing need to develop environmentally friendly nanoparticle synthesis methods that do not use toxic compounds in the synthesis protocol. As a result, Mexican Partners in the area of nanoparticle synthesis have turned to biomimetic or biological systems for inspiration. The use of plant extract is one of the most active areas to develop synthetic methods to obtain non-toxic and biocompatible AgNp. Fig. 3 shows the developed reaction conversion as function of nopal extract used in the reaction. As can be seen, the rate of AgNO3 conversion to AgNp is directly proportional to the amount of nopal extract used in reaction.

|

|

| Fig. 3. Effect of the nopal extract on the AgNps reaction conversion |

This process is defined to be highly efficient and silver content is close to the maximal obtained by using other synthetic methods. One of the main concerns of these nanostructures is to identify all the possible organic components present in the AgNps, mainly if these nanomaterials are intended to be used for medical or environmental applications. To scale up the production of AgNPs to higher volumes, the new reactor with the downstream process was developed and tried to isolate and purify the AgNPs for biomedical applications.

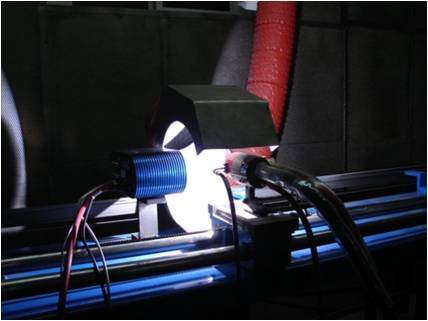

4) Plasma Spraying of HAP coatings containing Ag micro- Nanoparticles

The disc and rod samples for in-vitro and in-vivo tests, sedimentation of AgNp on their surface, adjustment of spraying and feeding parameters and deposition of HAP coatings on disk samples were made. Partners have fabricated cylindrical implants for rabbits and hip cup implants using the optimized plasma deposition technology

Implantation of cylindrical implants into rabbits legs, monitoring of rabbits state after surgical operation were made. The following works were made within this activity:

• Cytotoxicity analysis and SEM analysis of tissue cultures after incubation. Implants covered by HAP+NpAg3% and HAP+Ag3% (nanoparticles produced by biosynthesis) were incubated for 1, 2, 3 and 4 weeks in culture medium in incubator (37ºC, 5% CO2).

• Antimicrobial activity was evaluated against the ATCC 35984 Staphylococcus epidermidis (LGC Standards) strain. Anti-bacterial activity tests were made and have shown significant antimicrobial properties of the implant coatings containing silver nanoparticles.

• In vivo study was conducted on the group of rabbits, males. The titanium implant prototypes (cylindrical) were inserted into the rabbit’s legs. It was decided to use two methods developed in the frame of the Project for deposition of HA coating doped with Ag: (1) deposition of HA+Ag pre-mixed powder (10% of Ag); (2) deposition of initial HA coating with further sedimentation of AgNp

a) a) |

b) b) |

| Fig. 4. Hip cups fabricated by 2PS for testing and characterization a) without NpAg b) with NpAg |

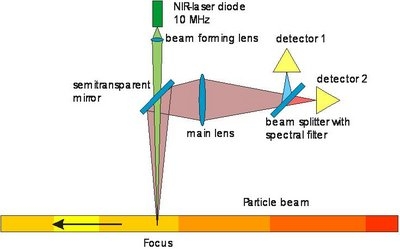

5) Diagnostic system for plasma spraying on-line monitoring of HAP

The precision control of plasma deposition parameters was needed to achieve the desired structure of the Hydroxyapatite coating with AgNp. This task was fulfilled with the new diagnostic system developed by IfU. The main idea of the measurement method consists on the illumination of passing particles by a pulsed infrared laser. The reflected part of the pulsed laser radiation signalised the passage of the particle through the measurement window. The time of flight is an inverted signal to the particle velocity. During the time of passage the emitted thermal radiation of the particle is captured by two fast detectors with different spectral ranges. The ratio of the two emission signals results in a fast temperature measurement. Therefore a single particle statistics for velocity and temperature is possible. This information is used to benchmark the quality of the particle beam.

a) a) |

b) b) |

| Fig. 5. Optical design (a)of introduced sensor and measurement arrangement (b) |

IfU has approved the developed measurement method during a lot of particle measurements at real thermal processes. The measurement equipment was optimised to HAP-plasma spraying process.

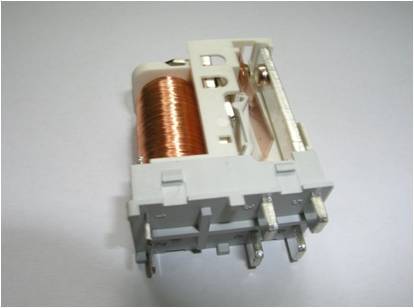

6) Electrical contacts based on Ag-based nanocomposites

Based on results of study of nanocomposite technologies in the industrial environment the bimetallic electrical contact components were fabricated, characterized and tested. Bimetallic contacts were made of BT6/1,5x3/3,3 type (both AgSnBi and AgZn materials), 10BW4/1x2/2,5 (AgRe material) and 15BW6/1,52x3/2,63 (AgSnO2Bi2O3 material). The technologies for production of nano-composite contact materials of Ag-Re10, AgSn02Bi203 10 and Ag-Zn010 type were transferred into pilot scale. The pilot installation for up-scaling of electrical contact production using the developed technology was completed with application of INM-INMET pilot plant equipment, and the first batch of electrical contacts was fabricated and sent for trials by the end-user. Contact rivets made of AgSnO2Bi2O310 nanocomposite material were implemented by RELPOL company in solar relays which were then tested to determine their applicability in operation.

a) a) |

b) b) |

| Fig. 6. Bimetallic contact rivet 15BW6/1,52x3/2,63 made of AgSnO2Bi2O3 (a) and solar relay with nanocomposite AgSnO2Bi2O3 contacts implemented (b) |

The work has resulted in generating Polish patent for Contact material Ag-Re and method for producing contact material. The second patent application has been submitted for Method for production of Nano-composite contact materials in silver matrix.

According to specification of the Project end-users, Silver nanoparticles (AgNp) and silver based nanostructured composites are believed to be used in a variety of other biomedical and industrial applications, such as an antimicrobial agents, lead-free solders, electric contact materials, gas-sensitive sensor, etc.

Within the Project there were created several publications. The following are the main ones:

1. J. Sulej-Chojnacka: Methods of recovering precious metals from jarosite type mining waste, Metal Forming, Periodical, v. 23, No.1, Poland, 2012, p. 45-56

2. S. Księżarek, M. Woch, D. Kołacz, M. Kamińska, P. Borkowski, E. Walczuk: Progress in fabrication technology of silver-based contact materials with particular account of the Ag-Re and Ag-SnO2Bi2O3 composites, Proceedings of ICEC-ICREPEC 2012, China, May 14, 2012

3. M. Ignatev, T. Rybak, G. Colonges, W. Scharff, S. Marke: Plasma sprayed hydroxyapatite coatings modified with silver nanoparticles, Acta Metallurgica Slovaca, Faculty of Metallurgy, Technical University of Košice, Slovaka, p. 20-29

4. S. Księżarek, M. Woch, T. Klir, D. Kołacz, M. Karpiński, K. Rudnicki: Environmentally friendly silver-based contact materials, ORES AND NON-FERROUS METALS, R57 (8, 2012), p.549-555

5. D. Garbiec, F. Heyduk: Sintering of titanium and hydroxyapatite by Spark Plasma Sintering, THE METALLURGIST – Metallurgic news, Volume LXXIX, No. 8, 2012, p. 569-574

Acknowledgements:

1. The research leading to these results has received funding from the European Union Seventh Framework Programme FP7/2007-2013 under grant agreement No. NMP4-CP-2011-263942.

2. Research work financed from public funds for science in period 2011-2013, granted for realization of international co-financed project. |